Weller Magnastat Autopsy and Repair

Immediately after soldering together my USB password thingy, my solder iron, the family heirloom Weller Magnastat stopped working. Some investigation showed that the base station was providing 24V AC voltage just fine, so I decided to unassemble the handpiece to see if something could be done. Here’s what I found:

It turned out my iron was salvageable; read on to learn a bit about the Magnastat and how I was able to repair mine.

Magnastat basics

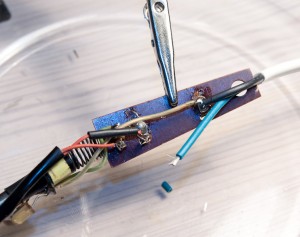

The construction of the device is surprisingly simple (see this image): The first (blue) wire from A/C power unit goes straight to the heating element (first red wire with black tube around it). The second (black) A/C wire goes through the magnastat switch (brown and green wires) and then to the second heating element wire (second red wire without the black tube). A capacitor is wired parallel to the switch. With limited A/C experience I’m not sure if it’s for blocking DC current, smoothing the switch action or letting a small amount of A/C current through.

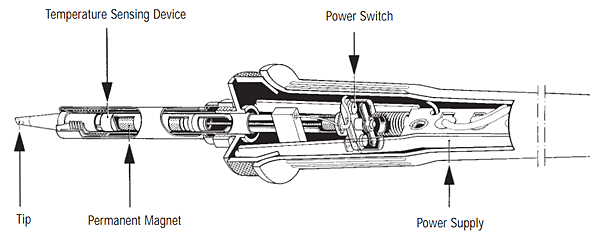

A long tube goes “out” the handle part into the iron tip, and the tip is placed at the head. The hollow tube above the tip is then placed over the tip and screwed to the base of the main assembly to keep the tip snugly in place. Here’s a diagram of the inner workings, from Cooper Industries’ website:

If you read a bit about the Magnastat, it turns out the temperature-controlling part, the “magnastat”, behind the tip is magnetic below a given temperature, and loses its magnetic properties above that: Initially the magnastat pulls the switch closed via a mechanism inside the long tube, but once desired temperature is reached, the magnetic property is lost and the switch opens. Once the tip cools down a bit, switch is pulled closed again, and so the temperature stays regulated.

Note that in my model the tip and the magnastat are one solid piece (magnastat is in the base of the tip), newer models have a separate magnastat and tip, and you can change the target temperature just by changing the magnastat part.

In my case, the problem seemed quite clear once I tested the power cord with a multimeter: Blue wire did not conduct at all. However, the insides were not in the best shape and nothing guaranteed that it would work after I replace the cord. And in any case I would need a new iron to fix it. So it was a good opportunity to consider byuing a new iron.

Alternatives for a new solder iron

I quickly decided I’d rather continue with a well-known brand than buy any of the questionable, cheap “digital solder stations” they had in Finland. A new Weller was an obvious choice since Hakko and most other respected brands are hard to get here. But after some surfing it started to seem that I would either be getting an inferior product to the Magnastat (products below 150 €), or I’d need to spend 220-390 in a new Weller of equal or better quality.

When considering other brands, many options of about equal or at most slightly better quality seemed to exist. However, in most discussion threads there was always someone who stated that induction based OKi (formerly Metcal) stations were superior to “traditional” irons. Unfortunately, I would’ve needed to order one outside Finland and without additional research, I was reluctant to spend 300 € on “some model and a few tips for that”.

So when faced with the alternatives, I decided to get a new iron for my existing station – after all, if it turned out the problem was with the base station, I could just get a regular 24V AC, 50W power source (actually, some people suggested that even DC might work). After wiring it into the base station, it started warming up immediately and worked like a charm. For less than 100 €, I once again had an excellent iron in my hands. It was time to see if I could salvage the broken old one, too!

Reviving the old Weller

I first thought I’d just replace the long part of the cord, as that was the most likely place for a broken wire. However, it turned out that long part worked just fine, and it was the last 5 cm that had broken. Warming up my new iron, I desoldered the existing cord and soldered a new one in its place:

After reassembling the handle, I plugged it back in, crossed my fingers and turned the power on. A power meter showed same wattages as with the replacement iron, so everything seemed to work well. After a while, a familiar “click” could be heard and the power dropped, indicating that the thermostat had survived the power cord transplant. Apart from an initial burning smell (I probably dislodged some soot and dust) everything seemed to work perfectly, and I was able to solder just like before. However, I decided to store the old iron as a backup and continue to use the new one, as it uses the newer LT tips and has that nice “brand new” feel to it!